1. Definition

Coating of a few nm up to 1-2

Why do we need them (add properties to substrate)

Electrical conductivity

Optical properties

Insulation

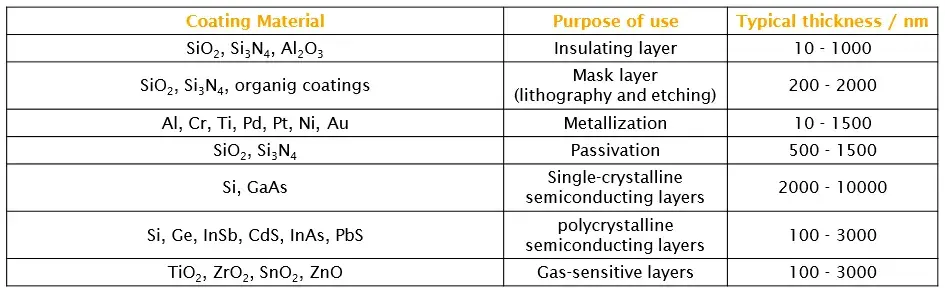

Examples

Optical: anti-reflection, interference effect

Color

Wear protection due to nanostructure (TiN)

Electrical conductors

2. Properties vs bulk material

Bulk properties : grain size influences mechanical properties

Thin films properties: mainly the prop. of the gas phase used to form the film

Coating properties: thickness, roughness, adhesion, hardness, composition, optical / electrical properties

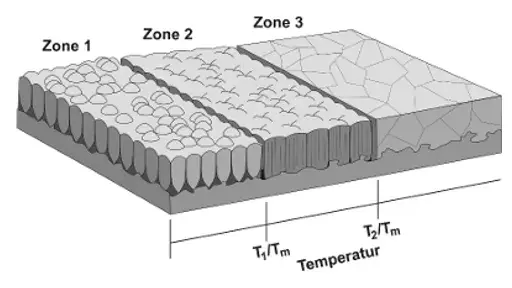

Structural zone model

The thin film is classed into 3 categories (zones)

Influenced by substrate temperature and roughness

Activation energy for diffusion process

Zone 1 : rough substrate, low temp → porous coating, weak adhesion

Zone 2 : higher substrate temp → less porous, better adhesion

Zone 3: further temp. increase → diffusion of coating, modification of crystal structure

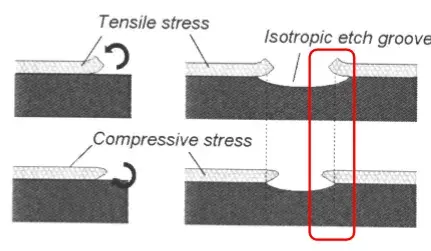

3. Residual stress

Insufficient adhesion may lead to delamination of a coating

Residual stress: compressive or tensile stress

Main cause : different shrinking coefficients between substrate and film

Different etching dimension from type of residual stress

Use residual stress for free-standing beams or curved mirrors