1. Materials

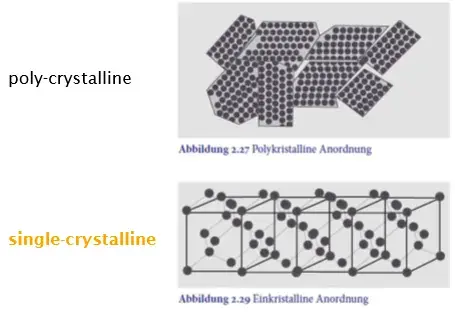

Difference from uSystem to other systems : unusual material like single crystalline Si

Properties dependent on length-scale (deformation of Si-pillars, color of gold)

In uSystem : substrate and coating or functional materials are distinguished

Substrate → Si, Glass, membrane

Functional → piezo-resistor, conducting path, isolations (SiO2)

Choice of material

Which functionality is needeed ?

Framework conditions

biocompatibility

Compatibility with other processes

Not the right properties → coating possible ?

2. Silicon wafers

Pure Si is required in uSystem : 99.9999999%

Impurity is 1 ppb ()

Impurities act as unwanted dopant

Needed for high yield

Single crystal in form of wafers

Properties are dependent on the single crystal orientation (miller index)

(111) has the highest binding density)

Why Si

Known properties

Availability

Semi conductor, conductivity

Single crystalline form has good mechanical properties (stability, reproducibility)

Perfect thermal oxidation for electrical isolation

Very good thermal conductivity

Fabrication

-

Fabrication of ultrapure Si

Metallurgic grade Si, obtained from heated Quartz sand, further heated with arc discharge giving Si

-

Si purification

Si is dissolved with HCL, then distilled and impurities stay in liquid

Trichlorisilane (SiHCL3) decomposes to SI via further evaporations steps

-

Creation of single crystal

Melted Si in vacuum or protective atmosphere

Pull the liquid Si up while rotating and it solidify as one crystal

-

Wafers from the ingot

Using a saw, the ingot is cut into wafers

Followed by lapping, etching polishing and cleaning

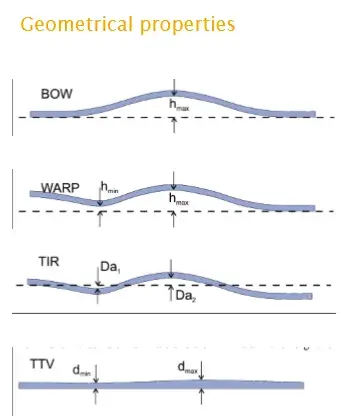

Wafers properties

Requirements: purity, small form deviation, surface quality with low roughness

From diameter 25 mm to 450 mm, thickness 775 um

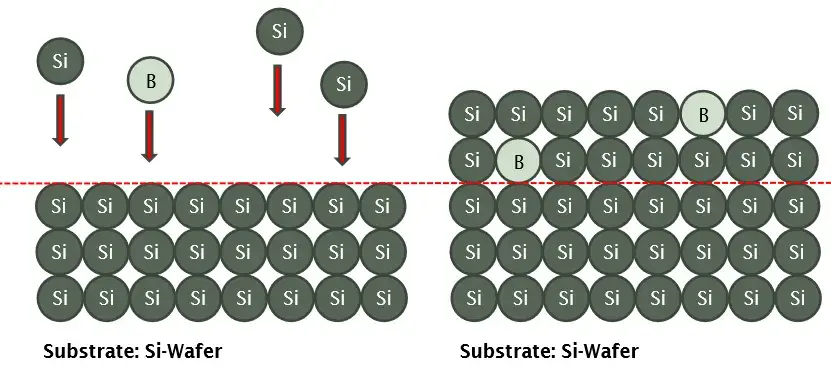

Modifying properties of SI

Doping

Adding small quantities of selected impurities

Goal: have specific resistance, different temperature coefficient

Dopers: boron (p-conducting), As, P (n-conducting)

Usage: as piezoresistive sensor, as etch stop layer

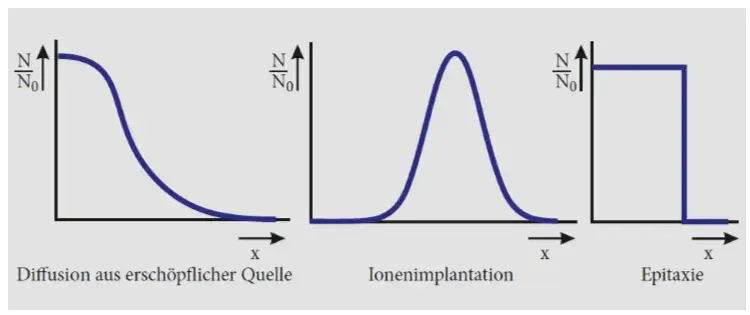

Process

Epitaxy: deposition of a coating from gas phase

Diffusion : gradient of impurities create exchanges at high temp

Ion implantation : ions are bombarded on the surface

3. Glasses

Rapid cooling from a melt into amorphous phase (no crystal)

Cheaper substrate, transparent, photostructuration on some glass

Typically silicate glasses or borosilicate

4. Piezoelectric materials

Piezo effect: Mechanical deformation leads to a charge seperation

→ Sensor

Inverse effect: apply voltage to induce charge seperation

→ actuator

D : displacement

d_ij : piezoelectric modules matrix in different crystal orientations

T : stress

and E are dielectrical relationships

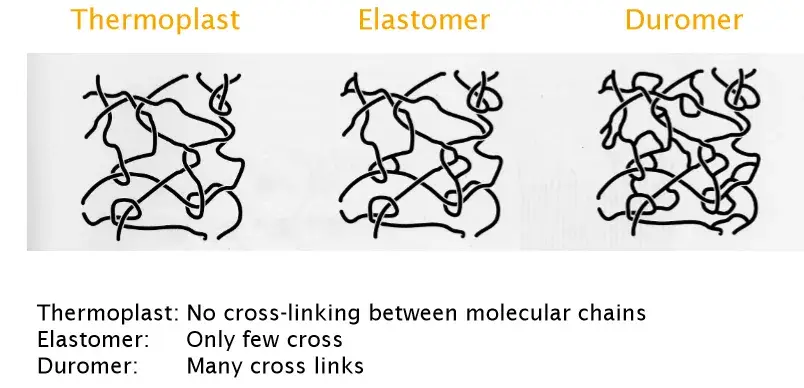

5. Polymers

macromolecules containing Carbon.

Polymers formed of monomers

Fabrication: polycondensation, polymerisation, polyaddition