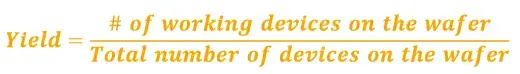

1 .Yield

Process is expensive and must be done in large quantities (batch processing)

yield = nombre de devices qui fonctionnent réellement en provenance du même wafer. (microparticules contaminent certains devices)

Miniaturisation

Everything becomes smaller but external contamination by particles is a bigger problem

particule size > 1/3 structural dimension = destruction of the component is likely

2. Contaminations & defects

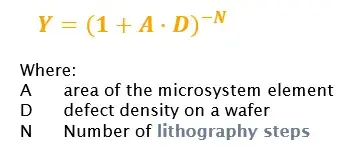

Main contamination sources

Main contamination occurs via particles but also chemical contaminants that are invisible under microscope

Defects caused by particles

Interruption of conductive path or short-circuit

Incorrect lithography

incorrect thermal oxidation

incorrect spin coating

incorrect coating deposition

A wafer exposed to normal air will be completely contaminated

Particle diffuse on the surface of the wafer

How to avoid disturbing particles ? → use a clean room

Defects caused by chemical contamination

Chlorine atom react with water → HCL and dissolve layers

3. Cleanrooms

How to measure number of particules: with light diffusion (measurement of scattered light)

Principles

Multiple zone : black, grey , white with different classes

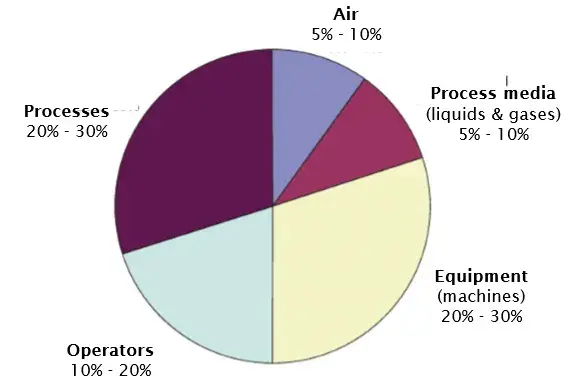

Reduce number of people

Don’t move

clean tools and materials when entering (with alcohol, wet chemistry process)

behavior is crucial

Air processing

Air is cleaned via filters and heat, humidity saturation and humidity removal

Temperature and humidity is controlled

Particle sources

Body: hair, grease, breath, sweat

Clothing: particles, fibers

Cosmetic: doping metals

Jewellery: metal particles