Structural analysis

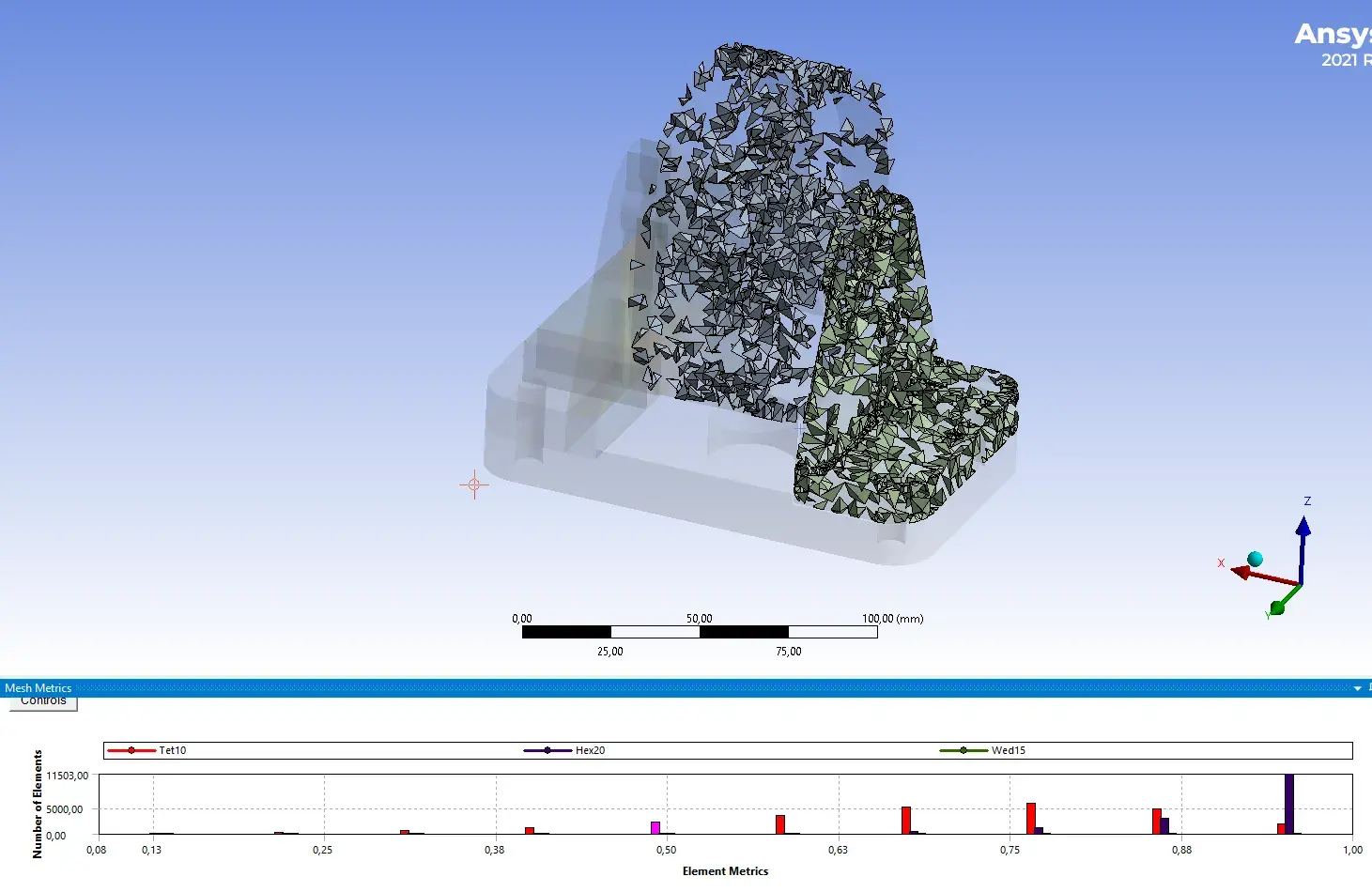

Meshing

Only use necessary mesh sizing, it will converge on the same value with finer mesh.

90 inner angles will create singularities and equivalent stress will rise with smaller mesh size. (Force act on no surface)

Bias for mesh sizing, merge mesh hard or soft

Span angle center : for radius, create finer mesh

<1M nodes = petit modèle

Mesh defeaturing : useful when 90 angle can be vereinfacht, avoid singularities..

in general, we need local mesh settings to have sufficient results

Method

Change meshing method : Mesh > method

Patch conforming: all edges (Kanten) in cad will create nodes frontiers in mesh (for tetraedrons)

Hex Dominant mesh : only use for parts with big volumes (not Blech for example)

Sweep : for prismatic bodies (same surface on top and bottom)

Multizone : autodetect were to sweep the model

Cartesian : do a cartesian Netz and quetch on the body (not really useful, maybe for 3d printed pieces, multiple layers)

Metrics display :

Press on the graph bar, to show some that are less good (first half of graph)

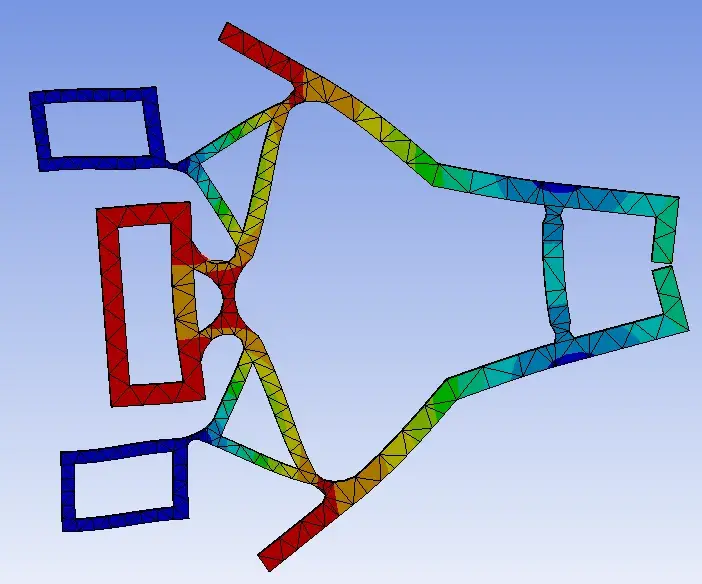

Inflation : when two pieces are pressed together, near holes for example

Face meshing : for faces with 4 edges

In general: try to reach a mesh that “looks” good, have finer mesh where data will be read.

Loads

A force is distributed on all the surface nodes selected, and will always point in the same directoin

A pressure, is always perpendicular to the surface, even if the deformation is big

Remote force → connect all nodes to a remote force (crée des moments)

Contacts

If 2 bodies are not bonded, the problem becomes not linear

Tips

Never do screw dimensioning in FEM, just read the forces on the beam and do the Nachweis by yourself

Modal analysis

About Eigenfrequenz analysis

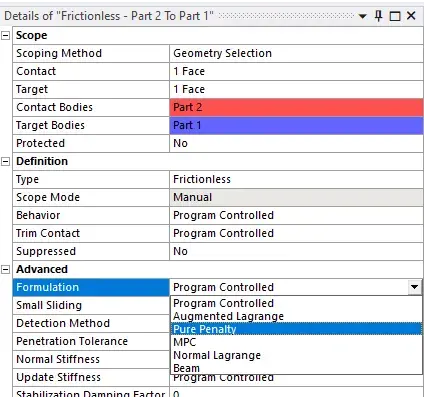

Contacts are made of springs, which should be removed (Contact region > Formulations): select MPC for multi body connected in modal analysis

Grosse influence à cause des prétentions (en provenance d’un modèle structurel) et des appuis

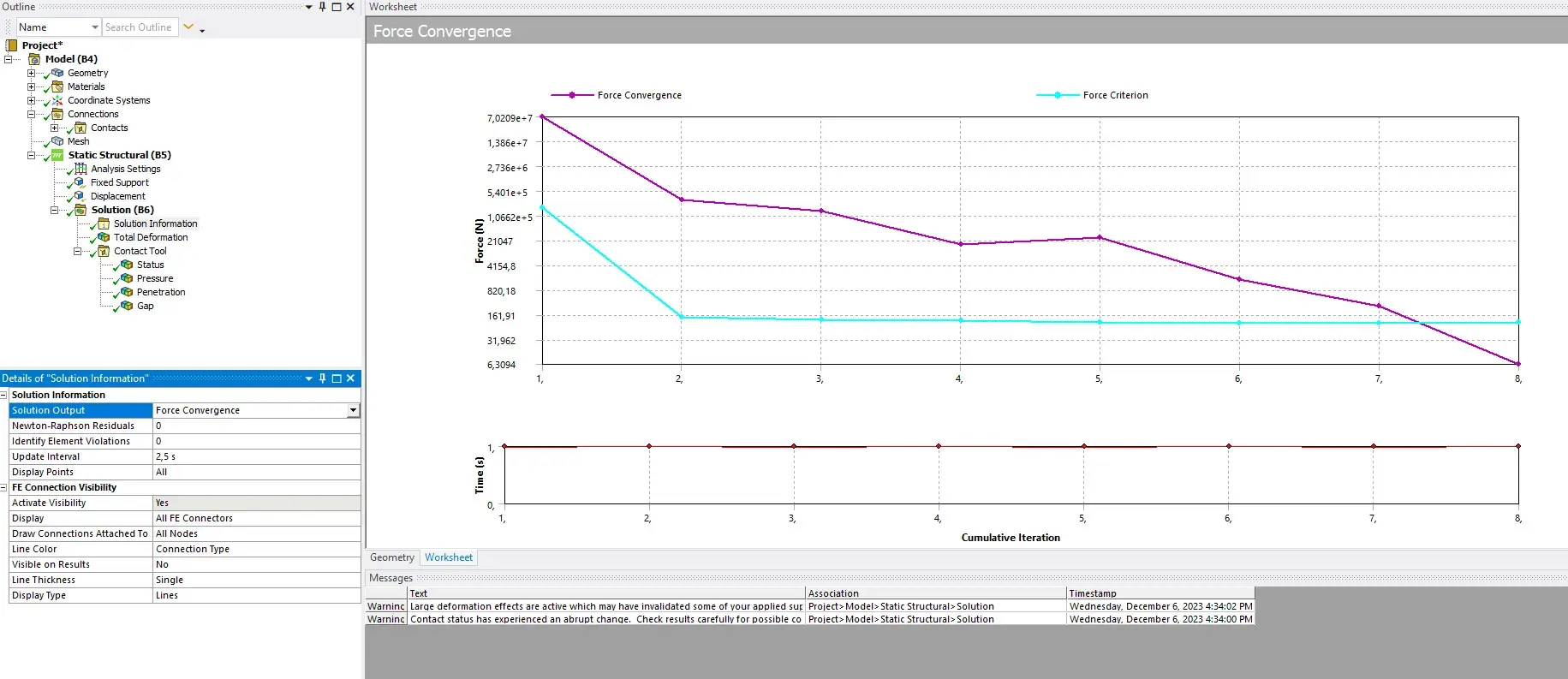

Grosse Verformung

Die Reaktionkräfte verhandern sich mit grossen Verformungen !

Analysis settings → activate large deflection

Iterative solutions necessary → take longer

Solution Information > solution Output > Force convergence

Contacts between components often lead to non linear systems

Non-linear materials (plastic Bereich) : super-elastic materials

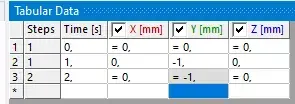

We need to work with the iterative diagram in system analysis to see at which step the model converged to a solution. For exemple, a 10 mm displacement will be divided into a lot of smaller displacement steps to solve.

Tips

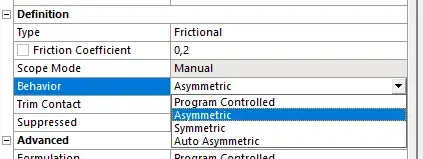

Contacts

The problems becomes non-linear !!

Often deactivate the auto detection of contacts

use bonded and frictionless or frictional

Select large deflection !

the mathematical model can be interpreted with some springs

can lead to oscillation in the simulation (the more rigid, the more problematic)

we need hard spring when we want to know the precise force on the contact

we can change normal stiffness (of the springs)

more stiff → harder to solve

Drag and drop

Drag the connection to the results to see the force reaction

Force at different timestamps

analysis settings > two steps

right click on data and deactivate at timestamp 2

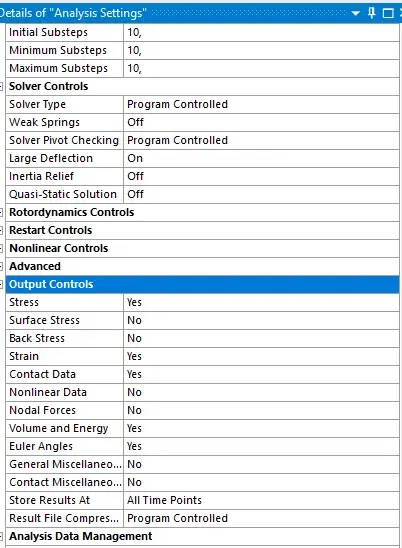

Analysis output

select all to yes

Material properties

Change material property to non linear (stress curve is bilinear) → let us see the plastic deformation of a piece